About

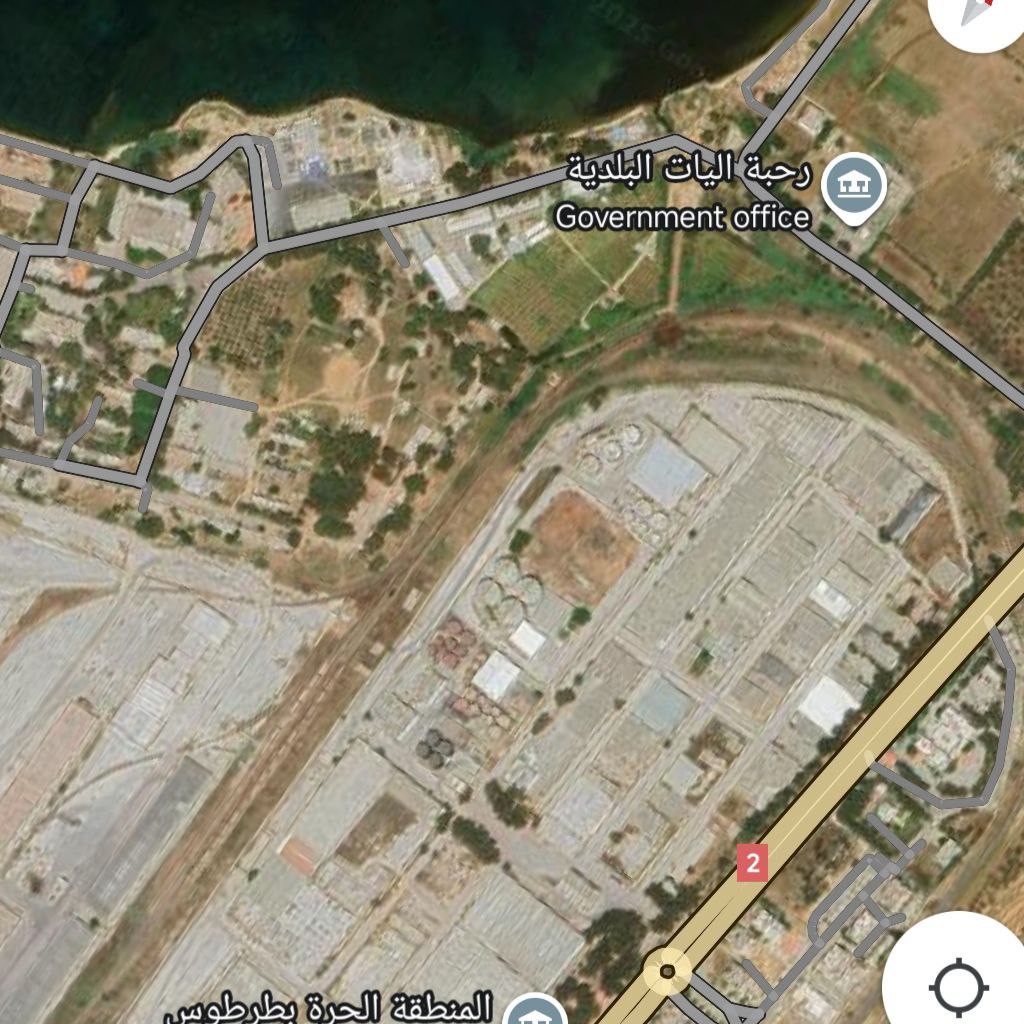

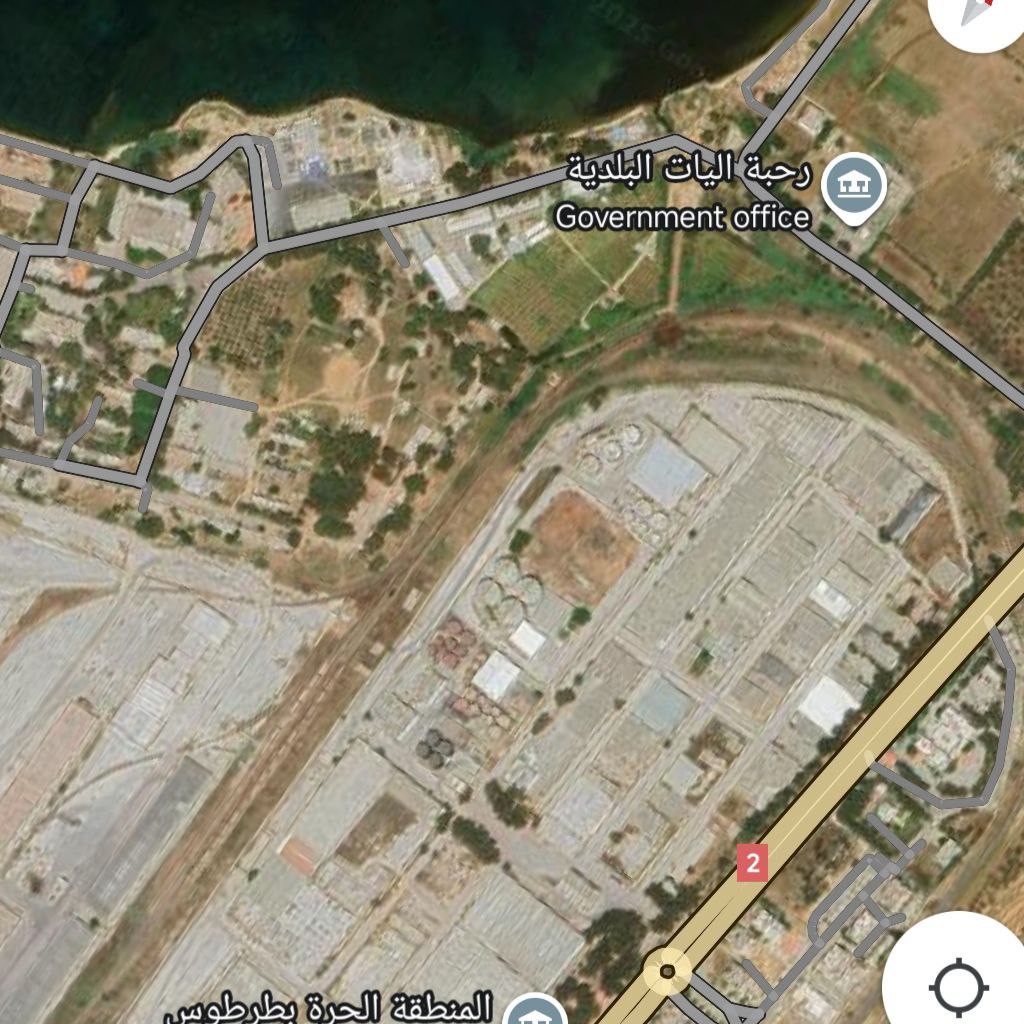

GVECO operates a large-capacity cold storage facility, capable of holding up to 4000 metric tons, equipped with continuous cooling and maintenance services hourly, seven days a week. This facility stands as the first and only one of its kind in the region, situated in Tartus, Syria, one of the pivotal ports in the area. The design and construction of this cold storage were carried out by GRASSO Germany.

Services

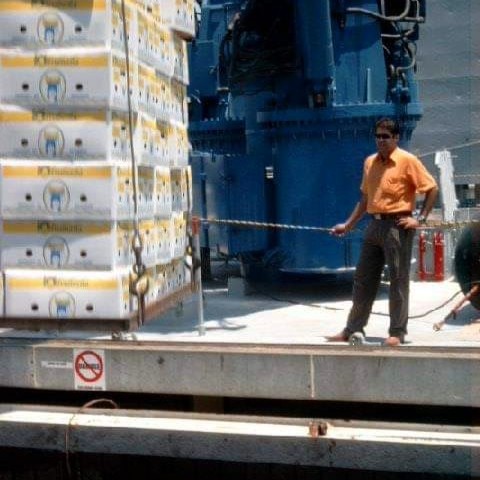

Unloading and Handling Fresh Fruit Shipments from Vessels to Cold Storage

Handling fresh fruit requires a precise logistics process that ensures product quality and food safety at every step. At our facility, we follow the highest cold chain and food-handling standards from the moment shipments arrive at the port until they enter our temperature-controlled storage chambers:

Initial Inspection Onboard the Vessel

At the start of unloading, our specialized team:

- Measures the temperature inside refrigerated containers or cargo holds.

- Verifies packaging integrity and checks for moisture or visible damage.

- Confirms shipment details with documentation (Bill of Lading – Packing List).

Unloading Using Certified Cargo Handling Systems

Cargo is offloaded with strict guidelines to protect sensitive produce:

- Minimizing exposure time to ambient outdoor temperatures.

- Keeping goods on clean, elevated platforms.

- Avoiding shocks or rough handling that may damage fruit.

Quality and Health Inspection at the Port Yard

After unloading, the shipment undergoes:

- Ripeness, humidity, and visual condition checks.

- Random sampling to confirm microbiological safety.

- Evaluation of logistical indicators (aroma, color, firmness, internal temperature).

Maintaining an Unbroken Cold Chain

To maintain product stability, we:

- Pre-cool trucks before loading.

- Monitor temperature and humidity during transportation.

- Use optimized, direct routes to minimize transit time.

Receiving and Documentation at the Facility

Upon arrival:

- Temperature logs are reviewed.

- Shipments are moved into a refrigerated receiving area.

- Batch records and traceability documents are issued.

Storage in Refrigerated or CA Rooms

Shipments are placed in specialized cooling chambers:

- Temperature settings adjusted per fruit type.

- CA systems regulate oxygen, CO₂, and humidity.

- Sensor-based monitoring with automated alerts.

Premium Cold and Frozen Storage Solutions for Food Products

At our large-scale warehouse, we combine advanced technology with global standards to ensure your food products remain fresh and safe, whether refrigerated or frozen. We offer comprehensive services designed to meet your needs and enhance the efficiency of your supply chain:

Premium Cold and Frozen Storage Solutions for Food Products

At our large-scale warehouse, we combine advanced technology with global standards to ensure your food products remain fresh and safe, whether refrigerated or frozen. We offer comprehensive services designed to meet your needs and enhance the efficiency of your supply chain:

Blast Freezing with Shock Technology

We preserve product quality and flavor through rapid freezing that halts bacterial growth and prevents spoilage while maintaining original texture and freshness.

Refrigerated and Frozen Storage to the Highest Standards

We provide precisely controlled storage environments for every type of product, ensuring consistent freshness and product safety throughout the storage period.

Optimal Box Selection for Each Product

We carefully select the appropriate boxes and containers for each product category, taking into account ventilation and protection during storage and transportation to achieve maximum efficiency and quality. Rely on us to preserve the value of your products and ensure they reach your customers with the highest standards of quality and safety.

Blast Freezing with Shock Technology

We preserve product quality and flavor through rapid freezing that halts bacterial growth and prevents spoilage while maintaining original texture and freshness.

Refrigerated and Frozen Storage to the Highest Standards

We provide precisely controlled storage environments for every type of product, ensuring consistent freshness and product safety throughout the storage period.

Optimal Box Selection for Each Product

We carefully select the appropriate boxes and containers for each product category, taking into account ventilation and protection during storage and transportation to achieve maximum efficiency and quality.

Features

Our cold storage facility is designed with cutting-edge technology to ensure maximum efficiency, safety, and reliability. Each feature is engineered to maintain ideal storage conditions for a wide range of products — guaranteeing consistent quality, freshness, and compliance with international standards:

Our cold storage facility is designed with cutting-edge technology to ensure maximum efficiency, safety, and reliability. Each feature is engineered to maintain ideal storage conditions for a wide range of products — guaranteeing consistent quality, freshness, and compliance with international standards:

Stable Temperature and Product Safety

The control system allows precise temperature adjustment within a range of 1 to 25°C, ensuring stable conditions that preserve product quality without spoilage. Our facility also includes two chambers capable of reaching –30°C, suitable for deep-freeze storage of sensitive goods.

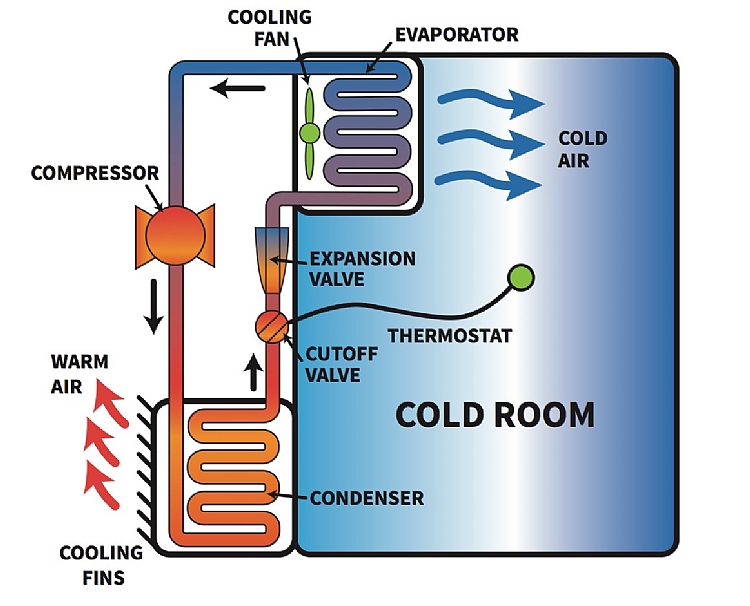

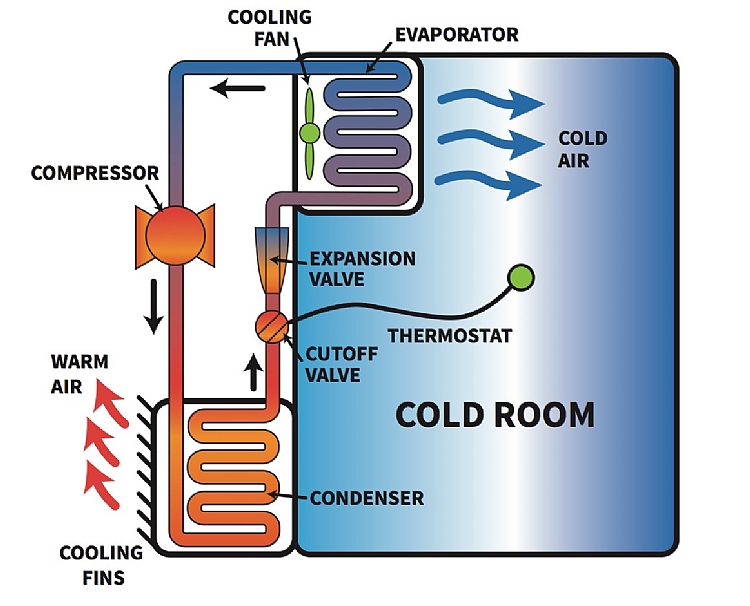

Flexible Cooling Systems Based on Product Requirements

Independent cooling units operating with Freon blast-freezing technology enable rapid temperature pull-down. When products do not require cooling or freezing, the system can be switched to ventilation or drying mode to provide optimal storage conditions.

Hygienic and Food-Safe Storage Environment

Storage areas maintain controlled humidity and ventilation, with an interior design that supports easy cleaning and reduces condensation and mold. This ensures a hygienic environment aligned with food safety standards.

Reliability and Backup Power Availability

A backup power system maintains continuous cooling during power outages, protecting stored goods and eliminating risk of temperature fluctuations.

Controlled Atmosphere (CA) Chambers for Long-Term Storage

Special CA rooms with airtight sealing and controlled gas composition support long-term preservation and maintain product freshness for extended periods.

Remote Monitoring and Control

Continuous temperature monitoring with instant alerts in case of any deviation, providing full visibility and peace of mind. Balanced airflow prevents freezing or spoilage of goods, while the interior layout supports efficient product organization and space utilization.

Stable Temperature and Product Safety

The control system allows precise temperature adjustment within a range of 1 to 25°C, ensuring stable conditions that preserve product quality without spoilage. Our facility also includes two chambers capable of reaching –30°C, suitable for deep-freeze storage of sensitive goods.

Flexible Cooling Systems Based on Product Requirements

Independent cooling units operating with Freon blast-freezing technology enable rapid temperature pull-down. When products do not require cooling or freezing, the system can be switched to ventilation or drying mode to provide optimal storage conditions.

Hygienic and Food-Safe Storage Environment

Storage areas maintain controlled humidity and ventilation, with an interior design that supports easy cleaning and reduces condensation and mold. This ensures a hygienic environment aligned with food safety standards.

Reliability and Backup Power Availability

A backup power system maintains continuous cooling during power outages, protecting stored goods and eliminating risk of temperature fluctuations.

Controlled Atmosphere (CA) Chambers for Long-Term Storage

Special CA rooms with airtight sealing and controlled gas composition support long-term preservation and maintain product freshness for extended periods.

Remote Monitoring and Control

Continuous temperature monitoring with instant alerts in case of any deviation, providing full visibility and peace of mind.

Balanced airflow prevents freezing or spoilage of goods, while the interior layout supports efficient product organization and space utilization.

Why Choosing GVECO Cold Storage is the Best Decision

There are several reasons why our cold storage facility serves as a cornerstone for a secure supply chain.

Among the most important reasons are:

There are several reasons why our cold storage facility serves as a cornerstone for a secure supply chain.

Among the most important reasons are:

Strategic Location of the Cold Storage Facility

The facility’s proximity to the port offers a significant logistical advantage, helping accelerate cargo transfer and reduce costs while maintaining the integrity of the cold chain and product quality. It also enables faster unloading and direct storage of goods, enhancing supply chain efficiency and operational flexibility — making the service more professional and reliable.

Integration

In addition to providing advanced refrigerated and frozen storage services for food products within our state-of-the-art facilities, we offer comprehensive shipping solutions that ensure efficient and professional cargo transportation. Our extensive expertise in selecting the ideal boxes and containers for each product type guarantees product quality and safety throughout every stage of transport. All these services are seamlessly integrated into a unified system that ensures smooth and secure supply chain management, delivering the highest levels of speed and precision — from origin to final destination.

Strategic Location of the Cold Storage Facility

The facility’s proximity to the port offers a significant logistical advantage, helping accelerate cargo transfer and reduce costs while maintaining the integrity of the cold chain and product quality. It also enables faster unloading and direct storage of goods, enhancing supply chain efficiency and operational flexibility — making the service more professional and reliable.

Integration

In addition to providing advanced refrigerated and frozen storage services for food products within our state-of-the-art facilities, we offer comprehensive shipping solutions that ensure efficient and professional cargo transportation.

Our extensive expertise in selecting the ideal boxes and containers for each product type guarantees product quality and safety throughout every stage of transport.

All these services are seamlessly integrated into a unified system that ensures smooth and secure supply chain management, delivering the highest levels of speed and precision — from origin to final destination.